Footwear Disruption: Saving the planet one pair at a time

By Delano Ellis

The possibilities for eco-friendly and sustainable practices in footwear is deep with opportunity and urgent in scope.

Ecological studies estimate that 20 billion pairs of shoes are produced annually, and over 300 million pairs end up in landfills after they have been worn. Even more disconcerting is the fact that the Ethylene-Vinyl Acetate (EVA) that comprises the midsole of most athletic shoes has a life cycle of 1,000 years in landfills.

I believe the footwear market can be sustainably disrupted, and I believe it’s our job as designers to make it happen. From thoughtful innovation to convincing user-centered product development, we have a responsibility to help preserve our resources through empathy, cognitive design and habit. Our future should include revolutionary practices in footwear manufacturing, material innovation, eco-friendly awareness, and thoughtful design in athletic and non-athletic footwear categories.

Over the past few years, many notable brands in the footwear industry have attempted tackling the challenge of post-consumer waste by employing upcycled thermoplastics and rubber materials for footwear design and construction. Nike made its Considered products and the Flyknit recycled running shoe. Simple Shoes made ecoSNEAKS. Teva made the sustainable Keagan shoes. Timberland made Brooklyn EK+. Converse made its Renew line. The North Face made camp slippers. Sperry made its BIONIC collection.

And those are all moving the right direction. What most companies are still systematically seeking to achieve is efficiently completing the closed-loop approach, similar to the cradle to cradle paradigm. The goal? Product processed to raw material and then back to product again.

Sure, it’s a beast of a challenge and requires a good bit of disruption through best practices, innovations in materials applied, assembly techniques, and a common voice that boldly resonates throughout the global footwear industry and marketplace. But it’s a challenge worth undertaking.

I am especially excited to see what Adidas is doing in its second eco-friendly athletic shoe concept, the FUTURECRAFT.LOOP. It is 100% recyclable in its entirety and able to be efficiently resurrected to its former self rather than be landfilled or turned into a water bottle or tote.

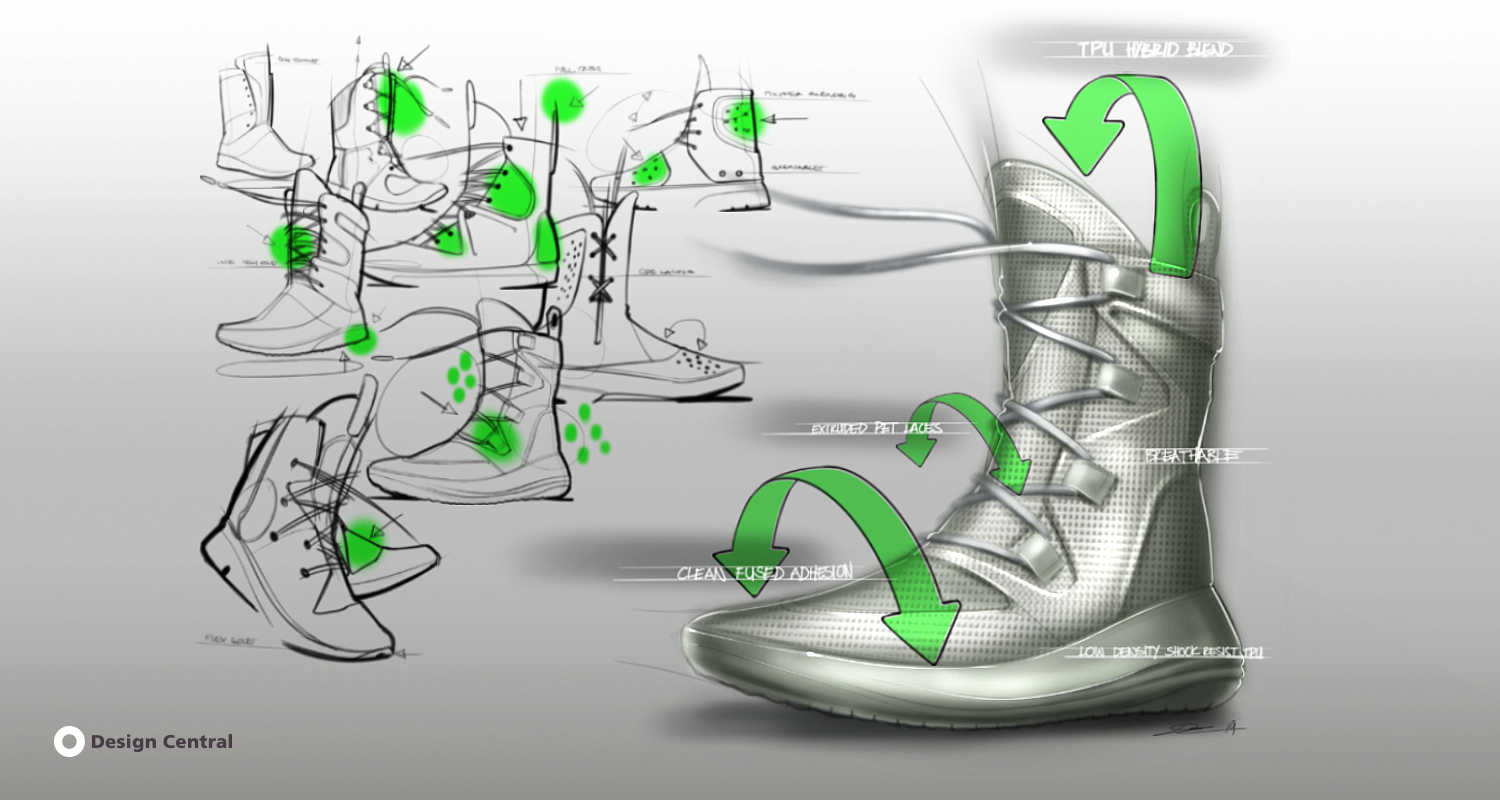

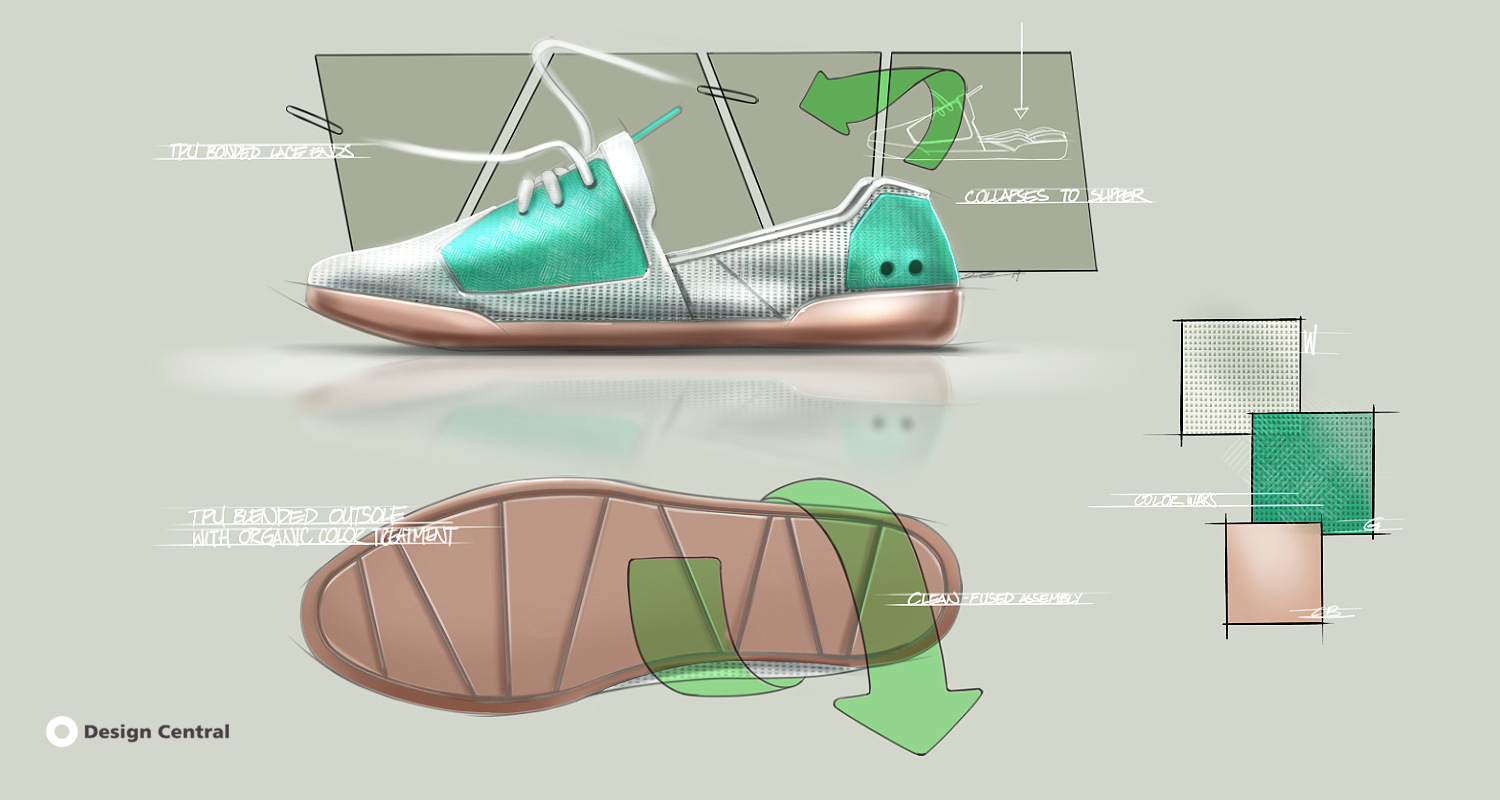

What tools can we use to achieve this all-inclusive, 100% closed-loop approach? PET and TPU fiber extrusion and spun textiles, non-woven polymer blends, co-molding, clean-fused adhesion, compression fitting, and colorfast/UV absorption organic dye formulas—to name a few.

The need is clear. The possibilities are endless. And the time is now.

Delano Ellis, best known as Deno, is a footwear enthusiast who enjoys studying the complexities of trends in the field. He is an industrial designer with a Master of Fine Arts Degree. His master’s thesis was titled Alternative Footwear: A Feasibility Design Study on Material Reuse. He proudly works at Design Central, which has worked with footwear companies such as Flexible Footwear and Nike. Interested in teaming to move the bar on footwear? Email Tim Friar at [email protected].